Whereas many robotics firms are constructing human-sized robots, or working to automate total factories, MicroFactory is as an alternative making an attempt to suppose large by constructing small.

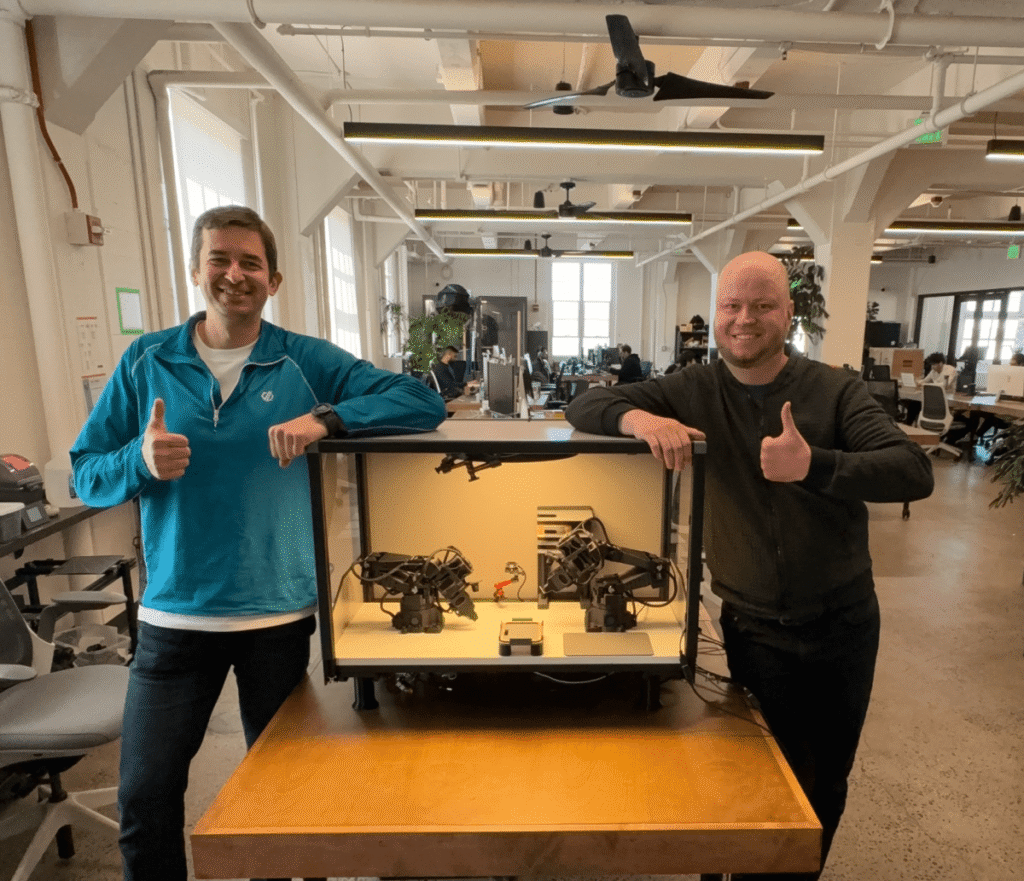

San Francisco-based MicroFactory constructed a general-purpose, tabletop manufacturing package that’s concerning the measurement of my Siberian Husky’s canine crate. This compact manufacturing unit consists of two robotic arms and could be educated by human demonstration, in addition to by means of AI.

“Basic function robots are good, however it’s not obligatory [to] be humanoid,” stated Igor Kulakov, the co-founder and CEO of MicroFactory, in an interview with TechCrunch. “We determined to design robots from scratch that may nonetheless be common function however not in human form, and this fashion, it may be achieved a lot less complicated, a lot simpler, in {hardware} and on the AI facet.”

Fairly than promoting particular person robotic arms, MicroFactory’s system comes as an enclosed however clear workstation, permitting customers to look at the manufacturing course of in actual time. The compact factory-in-a-box is designed for precision duties like circuit board meeting, part soldering, and cable routing. Customers can prepare the robots by bodily guiding the arms by means of complicated motions — a hands-on method that Kulakov says works quicker than conventional AI programming for intricate manufacturing sequences.

“Normally it takes couple hours, however on this method, the robotic significantly better understands what it ought to do,” Kulakov stated. “Once you rent folks, we nonetheless must spend time, like every week or one thing, to instruct these folks to then supervise their work. A producing firm, they have already got this time and sources to spend, and will probably be a lot simpler to coach a mannequin and to make it work on this method.”

Kulakov’s expertise with conventional manufacturing helped spark the concept behind MicroFactory.

He and his co-founder, Viktor Petrenko, used to run bitLighter, a producing enterprise that made moveable lighting tools for photographers. Kulakov stated it was tough to coach new staff on methods to full the manufacturing course of accurately. When developments in AI made it appear potential to automate this kind of work, they determined to leap on the chance.

Techcrunch occasion

San Francisco

|

October 27-29, 2025

Kulakov and Petrenko launched MicroFactory in 2024. It took them about 5 months to construct their prototype. Now the corporate has a whole lot of preorders from clients wanting to make use of the machines for varied functions, together with assembling electronics and even processing snails to be shipped to France for escargot.

MicroFactory simply raised a $1.5 million pre-seed funding spherical that included buyers like executives from the AI firm Hugging Face and investor-entrepreneur Naval Ravikant. The spherical values the younger startup at a $30 million post-money valuation.

Kulakov stated the corporate plans to make use of the funding to construct and ship out its items. The corporate is at the moment changing its prototype right into a industrial product that it hopes to start transport in about two months.

The corporate additionally plans to make some hires and proceed bettering its expertise, together with the AI fashions operating beneath the hood.

“Our development is said to constructing {hardware}, so we set the objective to extend it 10x annually,” Kulakov stated. “Within the first 12 months, we need to produce 1,000 robots, [about] three per day, and now we have the aptitude to do that. Then, [we want to] make increasingly productions.”